Fiber laser metal cutting machines have revolutionized the metal cutting industry, offering precision and speed like never before. With the rise of automation and digital manufacturing, manufacturers need reliable and efficient machines that can handle large-scale production. One of the leading manufacturers of fiber laser cutting machines, (company name removed), has been at the forefront of this technology since its inception in 2011.

With a registered capital of 50 million yuan, (company name removed) has invested heavily in research and development, resulting in cutting-edge fiber laser cutting machines that cater to a wide range of industries. The company boasts two assembly workshops and a digital green intelligent manufacturing demonstration workshop, equipped with 130 sets of various production and testing equipment such as large-scale gantry CNC machining centers. Additionally, (company name removed) has nearly 100 fixed assets billion, which is a testament to their commitment to quality and innovation.

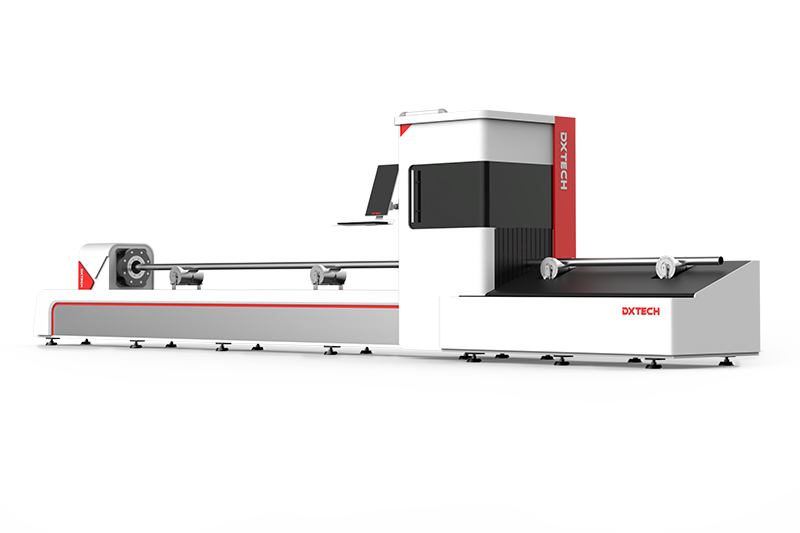

Fiber laser metal cutting machines work by using a fiber laser to produce a beam of high-density light that is focused on the material to be cut. This intense light melts or vaporizes the material, creating a clean and precise cut. Unlike traditional mechanical cutting processes, fiber laser cutting machines have no physical contact with the material, resulting in less wear and tear and fewer maintenance requirements.

Precision cutting is crucial in many industries, such as aerospace, automotive, electronics, and medical devices. Fiber laser cutting machines offer accuracy and repeatability, resulting in fewer errors and waste. Moreover, they can cut through a wide range of materials, including steel, aluminum, brass, copper, and titanium. With the ability to cut complex shapes and patterns, fiber laser cutting machines offer endless possibilities for design and production.

In conclusion, as the manufacturing industry continues to evolve, the importance of reliable and efficient machines cannot be overstated. (Company name removed) has been at the forefront of fiber laser cutting technology, investing in research and development to produce cutting-edge machines that cater to a wide range of industries. Precision cutting, versatility, and repeatability are just some of the benefits of fiber laser metal cutting machines, making them a valuable tool in the manufacturing industry.